Is efficient drainage truly crucial? A clear flow ensures a smooth operation.

Efficient drainage systems, whether for wastewater, agricultural runoff, or industrial processes, are paramount to maintaining functionality and preventing issues. This involves the removal of obstructions that impede the natural or engineered flow. In practical terms, this can include anything from clearing clogs in pipes to managing water flow in canals and ditches. Problems arise when materials accumulate, creating blockages that restrict movement. Effective solutions, therefore, depend on promptly identifying and removing these impediments.

The smooth flow of liquids and materials is vital for numerous applications. Uninterrupted drainage is critical in sanitation systems, preventing the build-up of pollutants and the spread of disease. In agriculture, efficient drainage is essential for crop yields and soil health. Historical examples of civilizations failing to manage water flow effectively underscore the long-standing importance of this issue. Consequences can range from property damage to significant economic losses. Understanding the mechanisms involved and implementing effective solutions directly contributes to overall well-being and prosperity.

Moving forward, we will delve into the technical aspects of plumbing systems, examining the types of blockages that commonly occur, and providing insights into sustainable solutions for maintenance and prevention.

Unblocked Flow

Efficient drainage systems, crucial for various applications, hinge on unobstructed flow. This encompasses aspects ranging from plumbing maintenance to agricultural practices. Maintaining clear channels and pathways is paramount for functionality and avoidance of complications.

- Drainage

- Pipe Integrity

- Water Removal

- Flow Management

- Prevention

- Maintenance

These key aspectsdrainage, pipe integrity, and water removalillustrate the interconnectedness of maintaining unobstructed flow. Poor drainage can lead to flooding and damage. Ensuring pipe integrity prevents leaks and clogs, which impede water removal. Proactive maintenance and preventive measures mitigate issues like blockages, ensuring consistent flow. Effective flow management strategies, encompassing the entire system, are vital for efficient operation in diverse contexts, from urban infrastructure to agricultural fields. For example, timely maintenance of irrigation systems prevents costly damages caused by waterlogging.

1. Drainage

Effective drainage is intrinsically linked to the prevention of blockages and the smooth flow of fluids. A critical aspect of this process is the maintenance of unobstructed pathways for water and other substances to move through systems, whether they are domestic plumbing, agricultural irrigation, or industrial waste management. The issue of blockages, often arising from accumulated debris or obstructions, directly impacts the functionality and efficiency of these systems.

- Pipe Integrity and Maintenance

Maintaining the integrity of pipes and channels is crucial. Corrosion, sediment buildup, or the accumulation of foreign objects can restrict the flow. Regular inspections and maintenance are essential for preventing blockages and ensuring sustained functionality. Examples include periodic cleaning of sewer lines or the removal of debris from irrigation ditches. Failure to maintain pipe integrity can lead to costly repairs and potential environmental damage.

- System Design and Topography

The design of drainage systems, particularly in relation to the natural topography of the land, significantly affects efficiency. Proper grading and slope angles allow water to flow freely. Improper design can lead to pooling, stagnation, and ultimately, blockage issues. Examples include drainage ditches designed with insufficient slope or construction projects failing to consider existing drainage patterns. A poorly designed system necessitates increased maintenance and presents greater risk of disruption.

- Material Composition and Resistance to Clogging

The materials used for constructing drainage systems influence susceptibility to blockage. Porous or easily clogged materials require more frequent maintenance. The selection of appropriate materials, resilient to abrasion and buildup, optimizes system longevity and reduces the risk of clogging. Examples include comparing the performance of different pipe materials in high-sediment environments or evaluating the effect of specialized coatings on erosion and build-up in canals. Appropriate material selection minimizes blockage concerns.

- Flow Rate and Capacity Management

Understanding and managing the flow rate of liquids within the system is key. Overloading the system with excessive flow surpasses its designed capacity, leading to blockages. Implementing methods to control and manage flow rates, such as controlling water intake or using strategically placed valves, prevents overload and maintains the system's efficiency. Instances of flooding or water overflow in urban areas highlight the consequences of inadequate flow capacity management.

In summary, effective drainage is fundamental to a functioning and efficient system. Maintaining clear pathways, addressing potential blockage points, and proactively managing flow are all essential components for avoiding issues related to accumulated debris or obstructions. These aspects, often overlooked, underpin the smooth operation of all types of systems, from plumbing to irrigation to industrial effluent removal. Addressing these elements directly impacts the ability to keep systems functioning freely.

2. Pipe Integrity

Pipe integrity is fundamental to unblocked flow within any system. Compromised pipe integrity directly leads to impediments in the movement of fluids, often manifesting as blockages. Corrosion, material degradation, or physical damage create pathways for debris and sediment accumulation, restricting the passage of liquid. This is particularly relevant in sewer systems, where accumulated waste and debris can quickly clog compromised pipes. Similarly, in industrial settings, corrosion in pipelines can cause blockages, impacting production and potentially leading to environmental damage.

Maintaining pipe integrity involves various measures, including using corrosion-resistant materials, employing protective coatings, and conducting regular inspections. Robust inspection procedures can detect early signs of damage, enabling preventative maintenance and reducing the risk of catastrophic failures. Regular cleaning and flushing procedures can also help to mitigate the accumulation of debris within pipes, even in the presence of minor damage. The proactive approach highlights the importance of understanding the link between pipe condition and flow obstruction. Examples include infrastructure projects prioritizing pipe materials resistant to chemical attack in specific environments or maintenance schedules incorporating video inspections for early defect detection in critical water mains.

Understanding the direct relationship between pipe integrity and unblocked flow is crucial for effective system design and management. Maintaining pipe integrity minimizes the potential for costly repairs and disruptions in service. Proactive measures to prevent damage and deterioration lead to a reduction in maintenance needs and ensure reliable operation. This not only enhances efficiency but also safeguards public health and environmental safety. The long-term cost-effectiveness of investment in preventative measures, including appropriate material selection and regular inspection protocols, is evident in the overall reduced disruption and operational efficiency gains.

3. Water Removal

Effective water removal is inextricably linked to the concept of unobstructed flow. Obstructions impede the removal process, potentially leading to stagnation, pooling, and subsequent issues. A system designed for efficient water removal relies on the absence of impediments within its channels and conduits. This includes preventing clogs and blockages from accumulating in drains, pipes, or other water conveyance systems. The fundamental principle lies in maintaining clear passageways for water to move unimpeded. Problems arise when these passages are blocked, whether by debris, sediment, or other obstructions. Real-world examples include flooded basements due to clogged drains, agricultural land affected by inadequate drainage systems, and industrial processes disrupted by blocked pipelines.

The importance of water removal extends beyond simple convenience. Unhindered removal is crucial for public health, environmental sustainability, and economic stability. In urban environments, effective drainage systems prevent flooding, protecting property and infrastructure. In agricultural settings, efficient water removal ensures healthy soil conditions, facilitating crop growth. Industrial operations rely on uninterrupted water removal to maintain production and prevent environmental contamination. In all cases, the capacity for efficient removal directly relates to the overall functionality of the system. Inadequate removal creates an environment conducive to the accumulation of contaminants and hazards. This underscores the crucial role water removal plays in maintaining a healthy and functional environment, mitigating risks associated with potential water-borne pollutants, and minimizing potential damage and disruptions.

In conclusion, water removal is an integral component of a system that prevents clogs and obstructions. Effective water removal systems rely on unobstructed flow. Understanding and implementing strategies for clear and efficient water removal mechanisms are essential for preventing problems related to stagnation, pooling, and the build-up of pollutants. The principle of unobstructed flow, integral to the functioning of diverse systems, underscores the practical significance of clear pathways for water to move through the environment, whether in urban environments or agricultural settings. This proactive approach minimizes damage, disruption, and environmental hazards associated with impeded water movement.

4. Flow Management

Flow management, in the context of preventing blockages and ensuring unhindered movement of fluids, encompasses a wide array of strategies. It's not simply about the velocity of flow, but also the capacity of the system to handle anticipated volumes and variations. Appropriate flow management directly impacts the prevention of blockages, which are often the result of exceeding the system's capacity or the presence of obstructions. Inadequate flow management strategies can lead to accumulating obstructions, resulting in diminished functionality and potential damage. For instance, an irrigation system lacking a sufficient flow control mechanism may lead to waterlogging and soil damage, while an inadequate sewer system can experience severe clogs, leading to public health issues. Similarly, industrial pipelines that lack robust flow rate monitoring and control mechanisms may lead to clogs and product build-up, hindering productivity and potentially causing environmental issues.

Flow management strategies are essential components in ensuring unblocked flow, not just for the smooth operation of systems but also for safety and environmental sustainability. These strategies involve various techniques, such as adjusting valves, using pumps for increased pressure, employing sensors to monitor flow rates and trigger alerts, and meticulously designing infrastructure to accommodate fluctuating flow demands. The selection and implementation of appropriate flow management strategies are directly related to the efficiency and reliability of the system. For example, in urban drainage systems, sophisticated flow management strategies can prevent flooding by anticipating peak rainfall events and adjusting water conveyance channels accordingly. Similarly, industrial processes often employ sophisticated flow monitoring and control systems to optimize production, minimize waste, and prevent clogs. Implementing effective flow management significantly reduces the occurrence of blockages, minimizes system downtime, and ensures compliance with safety regulations.

In summary, flow management is intrinsically tied to preventing blockages and ensuring unhindered flow in various systems. Effective strategies directly influence the efficiency, reliability, and safety of these systems. The practical application of appropriate flow management, from industrial processes to urban infrastructure, mitigates the risks of blockages, minimizes downtime, and safeguards against potential environmental and public health concerns. By understanding and applying these strategies, the smooth and unobstructed flow of liquids and materials is maintained, leading to improved performance and minimized risks.

5. Prevention

Prevention, as a critical component of maintaining unobstructed flow, encompasses proactive measures to avert blockages and ensure continuous operation of systems. The interconnectedness of prevention and unobstructed flow is evident in diverse contexts, from plumbing to industrial processes. Preventing blockages, often stemming from accumulated debris or materials, is a more cost-effective approach than addressing the consequences of a blockage. Early intervention, therefore, is vital. Examples include regular cleaning of gutters to prevent debris from clogging downspouts or the implementation of sediment filters in industrial pipelines.

Proactive measures such as routine maintenance and strategic design features play a significant role. Regular inspections and cleaning of drainage systems, for example, can prevent the build-up of sediment and debris that lead to blockages. Designing systems with appropriate slopes and dimensions is critical in preventing water accumulation and subsequent stagnation. The incorporation of appropriate materials in the construction of pipelines and channels also contributes to prevention by minimizing corrosion and buildup. This comprehensive approach, involving both structural design and operational practices, effectively reduces the potential for disruption and the need for costly repairs. A well-maintained sewer system prevents backups, protecting both infrastructure and public health.

Understanding the connection between prevention and unobstructed flow is essential for minimizing disruptions, avoiding costly repairs, and safeguarding against potential consequences such as flooding, environmental damage, and public health risks. Prevention is not merely a desirable practice; it is a cornerstone of efficient and sustainable system design and management. By prioritizing preventative measures, organizations and communities can mitigate problems before they escalate, ensuring the smooth and continuous operation of vital systems.

6. Maintenance

Maintenance practices are crucial for ensuring unobstructed flow within systems, directly impacting the prevention of blockages often associated with accumulated materials, often termed "unblocked slop." Regular maintenance minimizes the risk of disruptions, ensuring consistent functionality and avoiding costly repairs. This includes systematic inspections, cleaning procedures, and proactive identification of potential issues. Addressing potential problems early through maintenance mitigates the potential for significant disruptions to operations.

- Routine Inspections

Regular inspections of infrastructure, whether plumbing systems, drainage networks, or industrial pipelines, are essential. These inspections allow for the early detection of developing issues such as corrosion, cracks, or blockages, enabling timely interventions before they escalate into major problems. Routine checks can prevent small issues from progressing into substantial blockages, saving considerable time and resources. Visual inspections, video inspections, and pressure tests are critical tools for this purpose.

- Cleaning and Flushing Procedures

Regular cleaning and flushing of systems are vital for removing accumulated debris and sediments. This proactive approach prevents blockages and maintains optimal flow capacity. Cleaning frequency should be tailored to specific system characteristics, taking into account the type of materials transported and the propensity for buildup. For example, sewer lines require more frequent cleaning than water pipes in residential settings.

- Material Selection and Compatibility

Choosing materials resistant to corrosion, erosion, and the accumulation of materials is vital for long-term maintenance needs. Understanding the compatibility of materials with the transported substances minimizes the formation of deposits that lead to blockages. Using materials resistant to the corrosive effects of transported fluids, solids, and chemicals ensures prolonged system integrity. Proper material selection significantly reduces the need for frequent repairs and cleaning procedures.

- System Design Considerations

System design should incorporate features that facilitate maintenance and minimize blockage risks. These features include easily accessible components for cleaning, sufficient slope gradients to ensure unobstructed drainage, and strategically placed valves and shutoff points for isolating sections during maintenance. Careful design phases, including incorporating future needs, prevent issues that could later result in blockages and associated problems.

Effective maintenance, encompassing routine inspections, cleaning procedures, appropriate material selection, and strategic design considerations, significantly mitigates the risk of blockages in any system. A proactive, systematic maintenance approach ensures the longevity, safety, and efficient operation of vital infrastructure, ultimately preventing the costs associated with blocked systems and associated operational disruptions.

Frequently Asked Questions

This section addresses common questions related to maintaining unobstructed flow in various systems. Understanding these concerns can help prevent disruptions and ensure smooth operation.

Question 1: What causes blockages in drainage systems?

Blockages in drainage systems arise from a variety of sources. Accumulation of debris, such as leaves, twigs, and other organic matter, is a frequent cause. Similarly, improper disposal of materials like grease, fats, and oils can solidify and create obstructions in pipes. In addition, the buildup of sediment, mineral deposits, or roots growing into pipes can restrict flow. Improper disposal of industrial waste or hazardous materials can also introduce contaminants that cause blockages.

Question 2: How often should drainage systems be inspected and cleaned?

Inspection and cleaning frequency depends on several factors. Systems subject to frequent use, high-volume applications, or those in areas with significant debris accumulation require more frequent maintenance. Regular inspection and cleaning schedules should be developed based on specific system characteristics and usage patterns. Consultations with qualified professionals are often required to determine the ideal maintenance schedule for individual circumstances.

Question 3: What are the long-term consequences of ignored blockages?

Ignoring blockages can lead to a range of negative consequences. Accumulated debris can hinder the efficient removal of water and other fluids, potentially causing flooding, structural damage, and environmental hazards. In extreme cases, blocked systems can lead to health risks due to stagnant water. The long-term effects of neglected blockages can extend to increased maintenance costs, reduced operational efficiency, and significant repair expenses.

Question 4: What are some simple preventive measures to avoid blockages?

Implementing simple preventive measures can significantly minimize the risk of blockages. These include proper disposal of materials that could solidify or accumulate, such as grease and fats, using appropriate filters to catch debris in industrial settings, and maintaining proper slope gradients for drainage systems. Regular clearing of drains and gutters can also prevent the accumulation of debris.

Question 5: What should I do if I suspect a blockage in my drainage system?

If a blockage is suspected, the immediate response should be to contact qualified professionals for diagnosis and resolution. Attempting DIY repairs can worsen the problem. Professionals are equipped to identify the exact cause of the blockage and implement the appropriate solution, ensuring safety and preventing further damage. Prompt action is critical to mitigate potential consequences.

Understanding these FAQs provides valuable insights into maintaining unobstructed flow within various systems. By addressing potential problems proactively, organizations and individuals can ensure the smooth operation of critical infrastructure and systems.

The next section will delve into the technical aspects of plumbing system design.

Conclusion

This exploration of maintaining unobstructed flow emphasizes the interconnectedness of various factors. From the fundamental integrity of pipes and channels to the proactive management of flow rates, each aspect plays a crucial role in preventing blockages, often stemming from accumulated debris or materials. The article highlights the significance of regular maintenance, including inspections, cleaning, and appropriate material selection. Efficient drainage systems, crucial for public health, environmental sustainability, and economic stability, depend on unimpeded water removal. The consequences of neglecting these crucial elementssuch as flooding, infrastructure damage, and potential health risksunderscore the importance of proactive measures. Maintaining unblocked flow is not simply a matter of convenience; it is essential for the proper functioning of various systems and the well-being of communities.

Effective strategies for preventing and resolving blockages, combined with a commitment to consistent maintenance, are essential for long-term system health and stability. Addressing these issues proactively minimizes disruptions, avoids costly repairs, and safeguards against potential environmental damage. The focus on preventative measures demonstrates the critical role of proactive strategies in mitigating risks and ensuring the long-term efficacy of systems essential to modern society. Further research into innovative solutions for maintaining unblocked flow remains crucial for optimizing functionality and sustainability.

You Might Also Like

James Patrick Page III: The Latest News & InsightsHow Tall Is Merle Haggard? Height Revealed

Joey Merlino Daughters: Meet The Girls & Their Stories

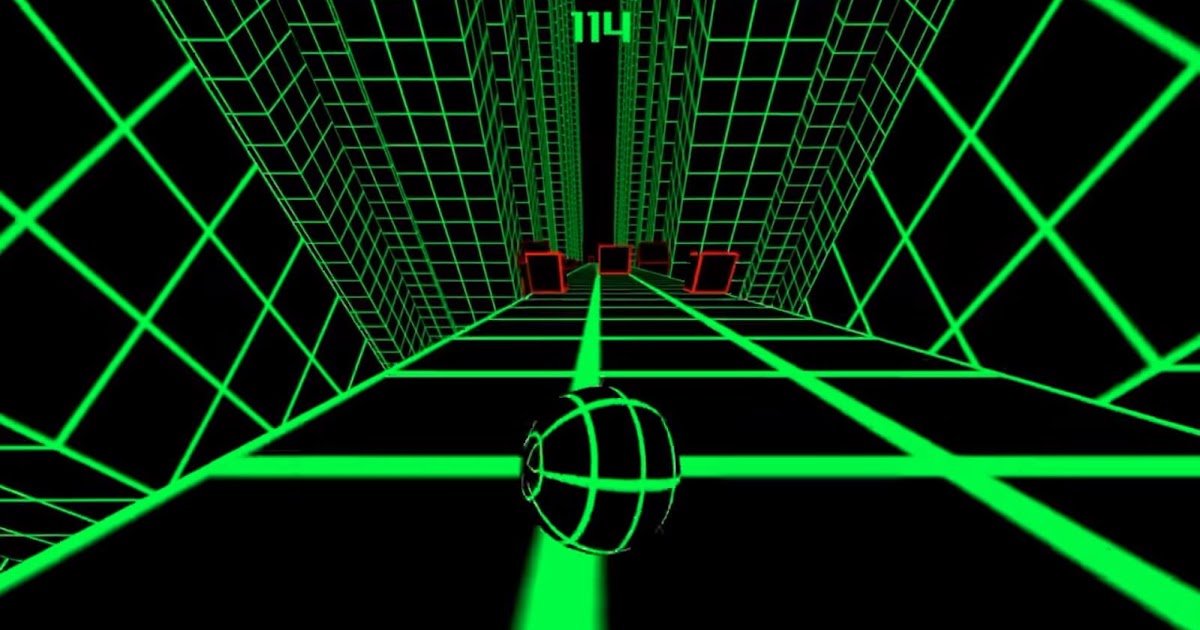

Slope Unbl: Understanding The Basics & More

Michael Spears Wife: Everything You Need To Know

Article Recommendations